No spill.

Always tight.

Designed to wrap perfectly around tube lights, these grids keep their shape and block unwanted spill, even in dynamic setups or tight spaces.

SNAPGRID®

FOR TUBES

CONTROLLED LIGHT

TUBE LIGHT. CONTROLLED RIGHT.

Precision light control - made easy for tube-style fixtures.

Tubes offer a unique lighting aesthetic - but when you need to shape and direct the light, SNAPGRIDS® are the ideal solution. Tailored to tightly fit the tube, these lightweight fabric grids mount directly and give you full control without changing the character of the light.

Designed to wrap perfectly around tube lights, these grids keep their shape and block unwanted spill, even in dynamic setups or tight spaces.

Setup is a breeze with simple hook-and-loop fasteners that attach directly to the tube. No extra hardware or tools are required.

SNAPGRID® add virtually no size to your tube setup - making them ideal for rigging, handheld use, or tight locations.

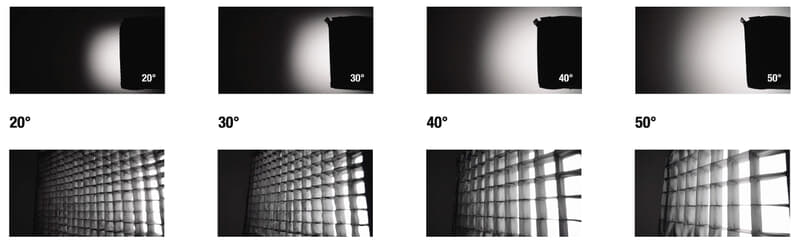

Choose from 20°, 30°, 40°, 50° and our 30°/50° combo angles.

Using an LED panel without accessories often results in wide, uncontrolled light spread and unwanted spill, especially on backgrounds or lens surfaces. A Direct-Fit SNAPGRID® narrows the beam, adds directional control, and helps keep the light exactly where you want it—without reducing the softness of the source. It’s a quick way to shape light cleanly, without changing your fixture setup.

A Direct-Fit SNAPGRID® attaches directly to the LED panel, offering beam control without altering the size or softness of the light—ideal for tight setups or minimal gear. A Softbox Grid mounts to the front of a softbox, which increases the light’s surface area for a softer output. The Softbox Grid shapes that softer light, while the Direct-Fit Grid shapes a harder or semi-soft source directly from the fixture.

The degree of a frost grid—like 30°, 40°, 50°—refers to the beam angle of the light that’s allowed to pass through the grid.

The Degree = Beam Spread

If you’re choosing one for your butterfly setup, think: how much spill can you afford?

Built from tough, precision-stitched fabric, these grids are made to endure the demands of professional sets—maintaining their shape, tension, and performance over time.

The degree is determined by the size of the cells in the grid, the depth remains constant on all our DoPchoice Grids.

BOX CELL Structure:

Pros:

Cons:

HONEYCOMB Structure:

Pros:

Cons:

SQUARE CELL Pattern:

Pros:

Cons:

RECTANGULAR CELL Pattern:

Pros:

Cons:

Disadvantages Interlocking system:

Advantages of the fully sewn cells in every DoPchoice Grid:

4 Items Found

Filters